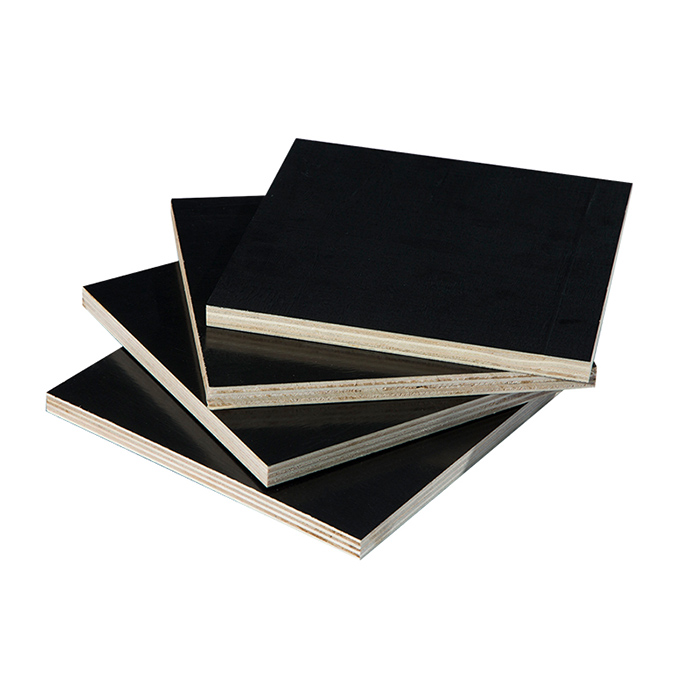

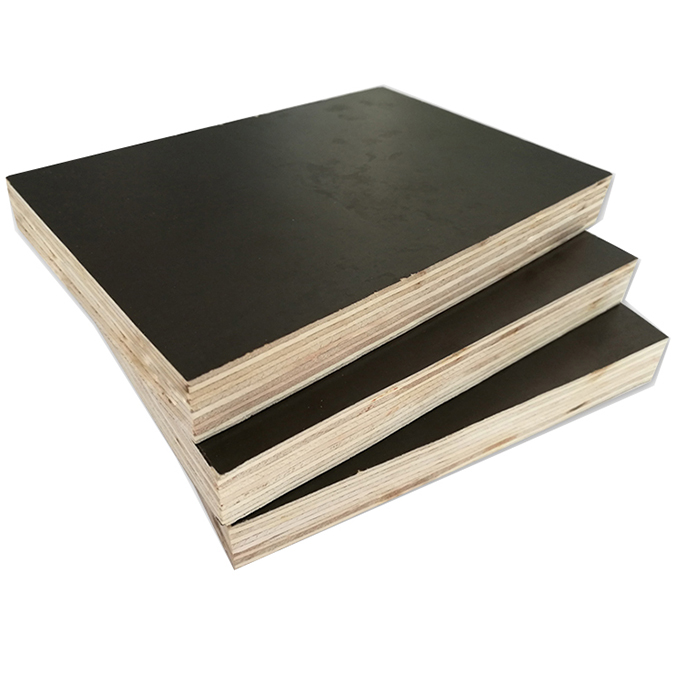

Film faced plywood

-

Hot

Construction plywood

1) High bending strength.

Email Details

2) little linear expansion coefficient.

3) Strong nail holding.

4) Moistureproof and easy work.

5) Tight construction and high strength.

6) No ratten or decay.

7) Low formaldehyde emission.

8) If put in boiling water for 48 hours, it is still glue sticking and nondeformed.

9) If used abide by the illustration strictly, it can be reused more than 10 times.

10) Solve the problems of leaking and rough surface during construction process, particular suitable for watering concrete. -

phenolic plywood/board

1) Light weight, more suitable for high-rise building and bridge construction.

Email Details

2) Large format, with the maximum format of 2440mm X 1220mm, to reduce the number of seams and improve the working efficiency of die support.

3) No warping, no deformation, no cracking, good water resistance. -

Hot

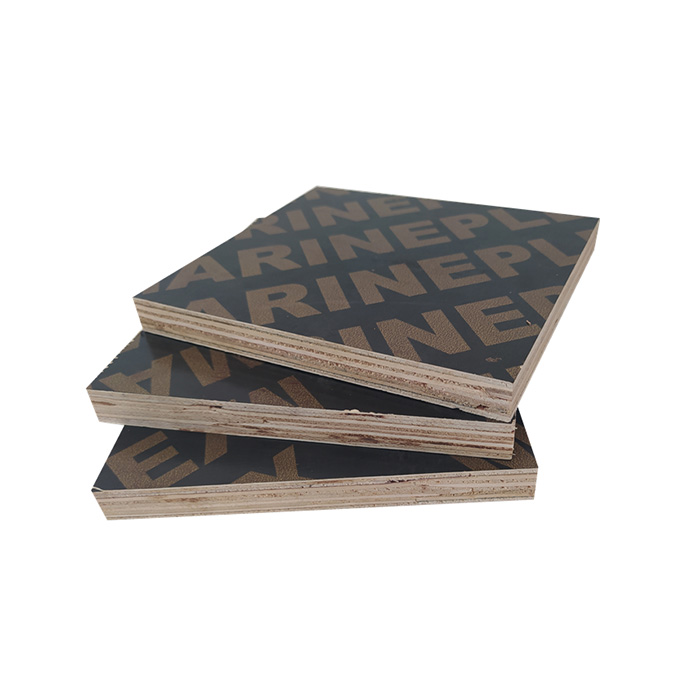

black brown film faced plywood

1. Transference to concrete is set up very easily, so good for construction work.

Email Details

2.Waterproof, Wear-resistant, anti-cracking. -

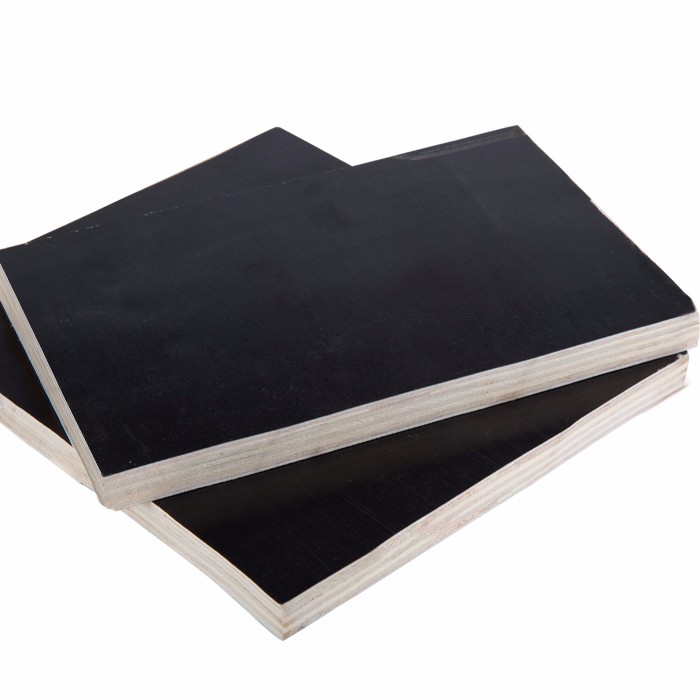

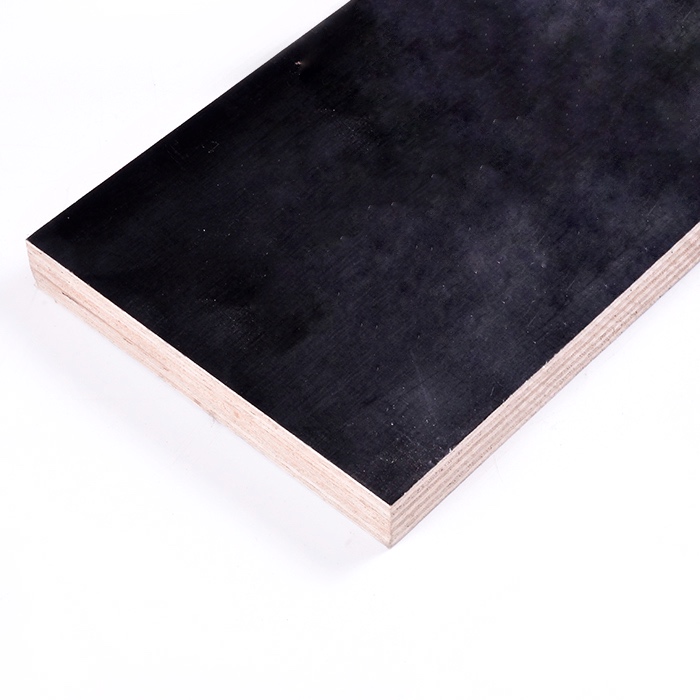

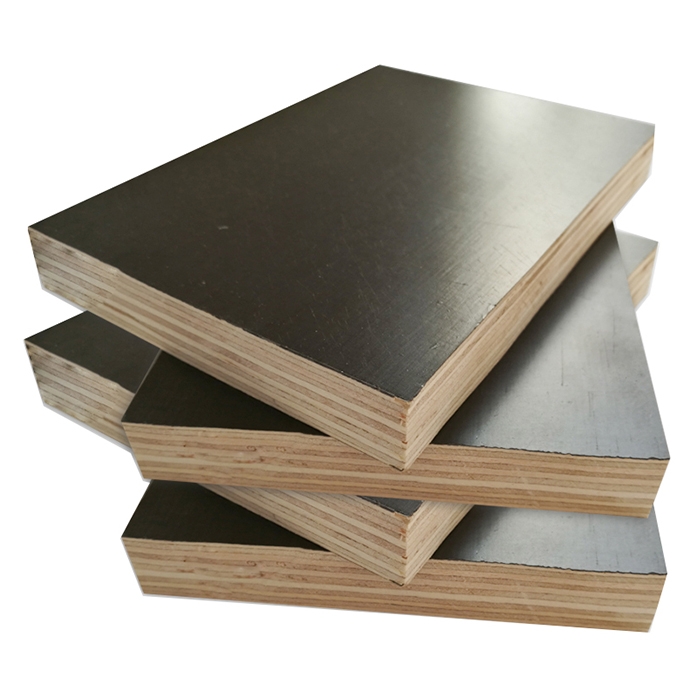

black film faced plywood

1. Transference to concrete is set up very easily, so good for construction work.

Email Details

2.Waterproof, Wear-resistant, anti-cracking.

3.After installation of concrete, the surface looks like a mirror. (The cement does not stick.)

4.Environmentally friendly.

5.It can be used for a long time, and for the initial price paid for the material, you will feel its worth over time -

marine plywood for construction

1) High bending strength

Email Details

2) little linear expansion conefficient

3) Strong nail holding

4) Moistureproof and easy work

5) Tight construction and high strength

6) No ratten or decay

7) Low formaldehyde emission

8) The produces are suitable for the construction of viaduct and tall frame buliding

9) If used abide by the illustration strictly, it can be reused more than 50 times

10) Solve the problems of leaking and rough surface during consruction process, particular suitable for watering concrete. -

formwork plywood

1. Transference to concrete is set up very easily, so good for construction work.

Email Details

2.Waterproof, Wear-resistant, anti-cracking.

3.After installation of concrete, the surface looks like a mirror. (The cement does not stick.)

4.Environmentally friendly.

5.It can be used for a long time, and for the initial price paid for the material, you will feel its worth over time -

Film laminated plywood

1) Easy to demould, release agent free, nonstick cement, concrete surface is very smooth.

Email Details

2) Light in weight, easy to use, can be cutted to any size.

3) More reuse times than normal film faced plywood.

4) Waterproof performance is perfect and wear resistant

film faced shuttering plywood -

brown film faced plywood

1)Transference to concrete is set up very easily, so good for construction work.

Email Details

2)Waterproof, Wear-resistant, anti-cracking.

3)After installation of concrete, the surface looks like a mirror. (The cement does not stick.)

4)Environmentally friendly.

5)It can be used for a long time, and for the initial price paid for the material, you will feel its worth over time -

Hot

18mm film faced plywood

1)Transference to concrete is set up very easily, so good for construction work.

Email Details

2)Waterproof, Wear-resistant, anti-cracking.

3)After installation of concrete, the surface looks like a mirror. (The cement does not stick.)

4)Environmentally friendly.

5)It can be used for a long time, and for the initial price paid for the material, you will feel its worth over time