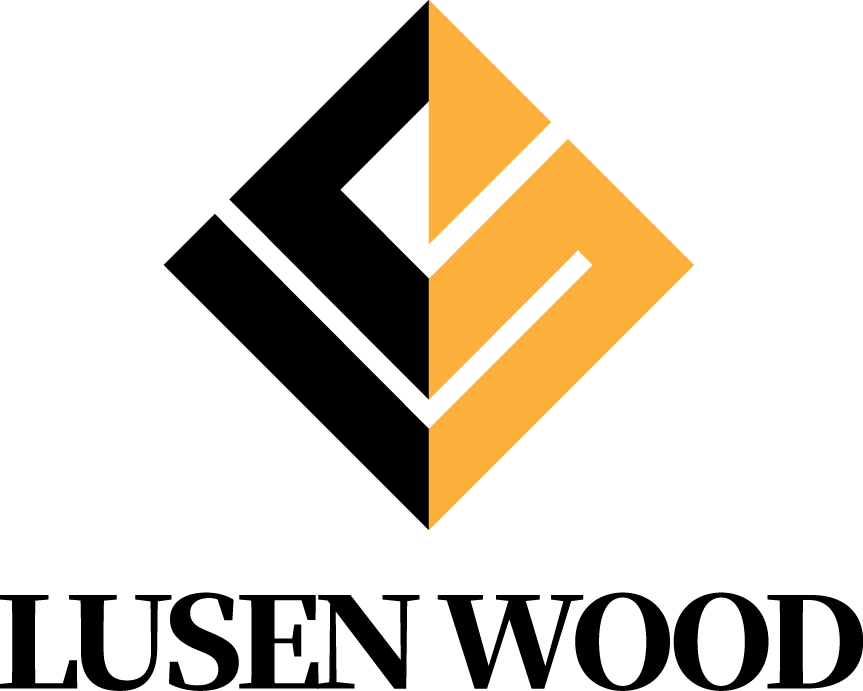

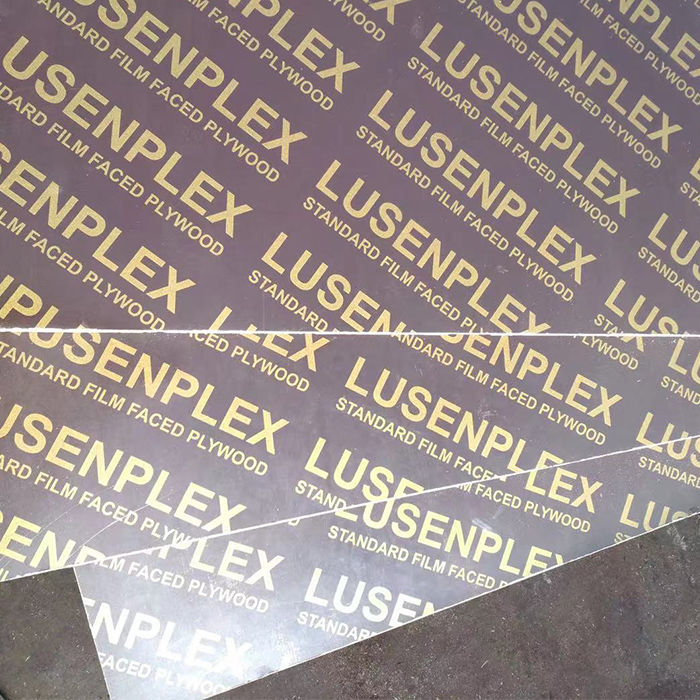

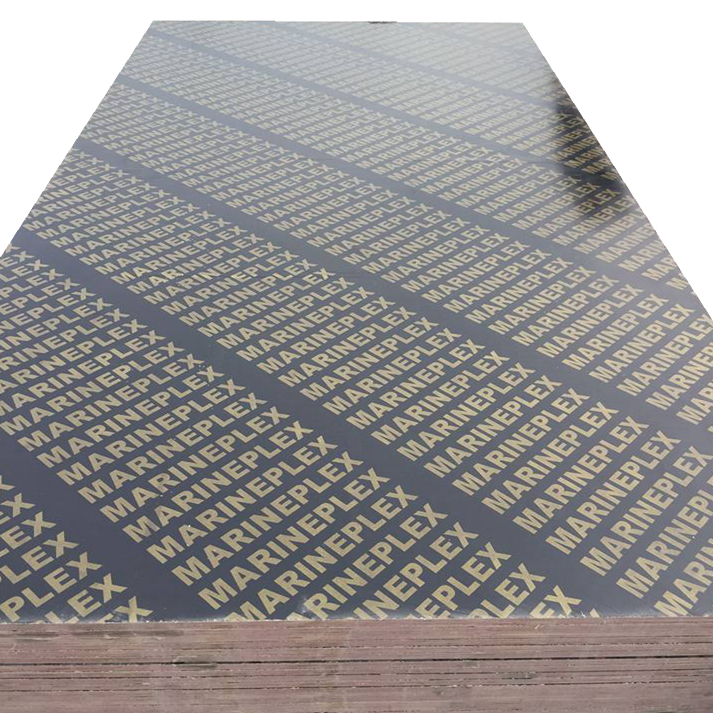

brown film faced plywood

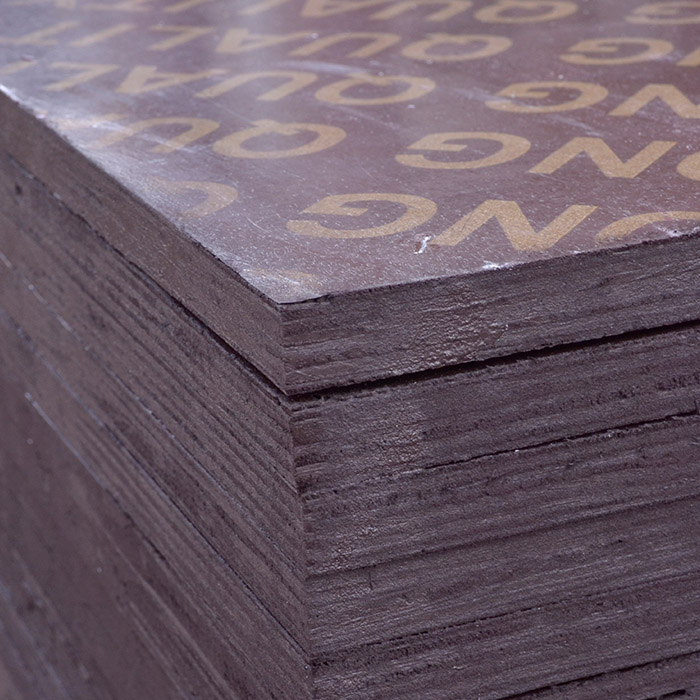

1)Transference to concrete is set up very easily, so good for construction work.

2)Waterproof, Wear-resistant, anti-cracking.

3)After installation of concrete, the surface looks like a mirror. (The cement does not stick.)

4)Environmentally friendly.

5)It can be used for a long time, and for the initial price paid for the material, you will feel its worth over time

Brown film faced plywood

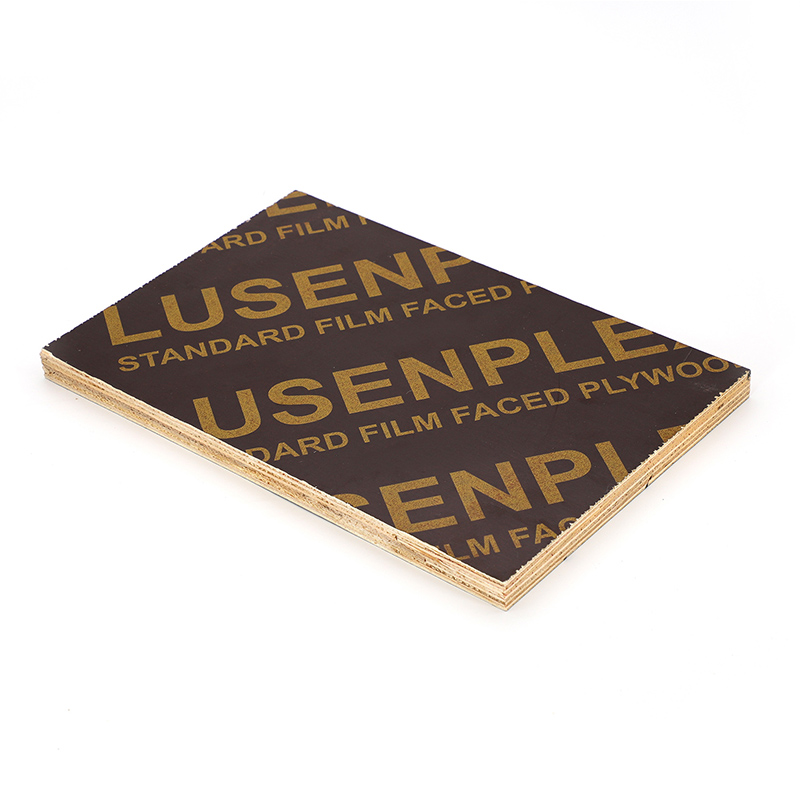

Size: 915X1830mm,1200x2400mm, 1220x2440mm,1250x2500mm

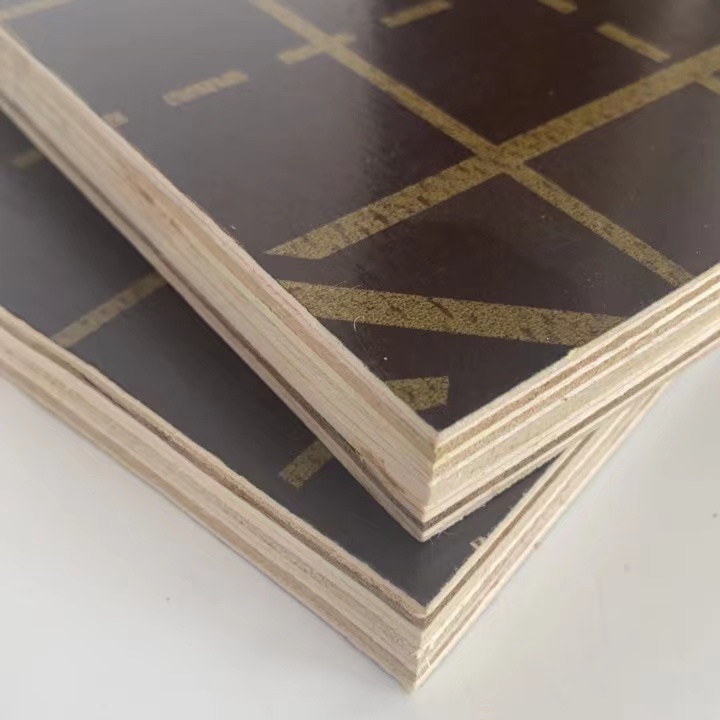

Thickness: 9mm, 12mm, 15mm, 17mm, 18mm, 21mm, 24mm etc.

Glue: Melamine, WBP, Phenolic, E1, E2 etc.

Certificate: CARB, CE, ISO9001

Widely use: Construction engineering, Scaffold board, Building operations, Viaduct construction.

Features: Coating the film faced plywood with high-quality import films ensures hardness and damage resistance. It can be used in conditions of high temperature drop, influence of moisture, detergent cleaning and provides protection against termites.

Main material | Eucalyptus, poplar, birch etc |

Glue | Melamine, WBP, Phenolic, E1, E2 etc. |

Size | 1220*2440mm, 1160*2440 mm or custom |

| Thickness | 9mm,12mm,15mm,17mm,18mm,21mm,24mm etc. |

| Face/Back | Black, brown, green, and red. |

Moisture content | 8%~15% at shipment time |

| Packing | Standard export packing: pallet with plastic and metal strips. |

Tolerance | T: ±0.5mm; W: ±2mm; L: ±2mm |

| Application | construction, engineering |

MOQ | 20CBM or 1*20GP |

Film faced plywood is resistant to corrosion attack and water, easily combined with other materials and easy to clean and cut.

Treating the film faced plywood's edges with waterproof paint makes it highly water-and wear-resistant.

Due to its durability and easily handled surface, it can be used in open environment in construction and building.

e.g. warehouses, railway wagons, floors and sidewalls of trucks etc.