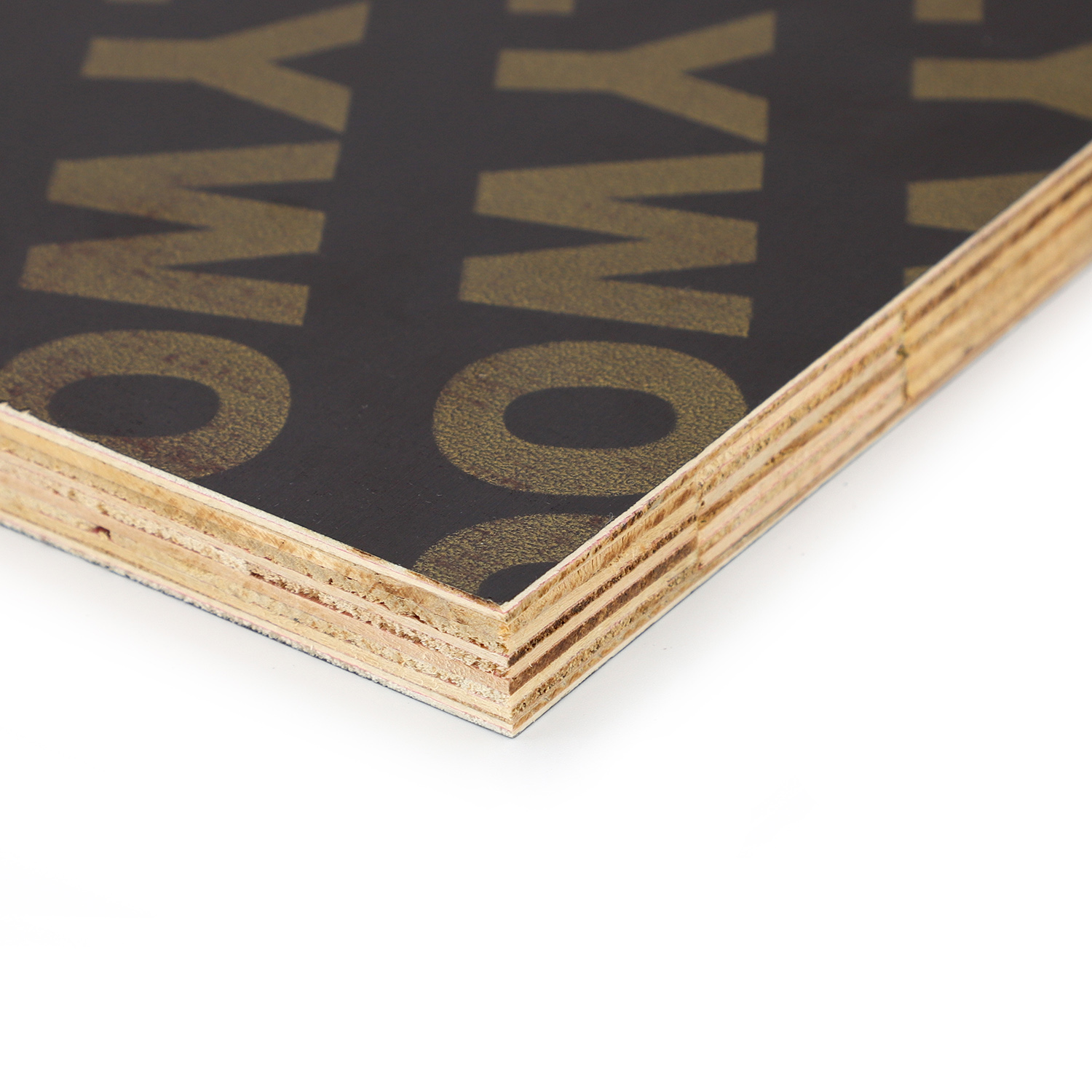

Film faced plywood

-

film faced plywood with brown film

1, Anti-smoke: It is made of PVC high-gloss film and easy to clean.

Email Details

2, wear resistance: special PET layer, sturdy and durable.

3, anti-humidity: surface film, reduce the direct contact between water and aluminum, and strong durability.

4, good touch: the surface has a film, the touch is smooth, changing the metal material cold and single feeling.

5, More colors: a variety of colors to choose from.

6, the price is moderate, cost-effective -

Hot

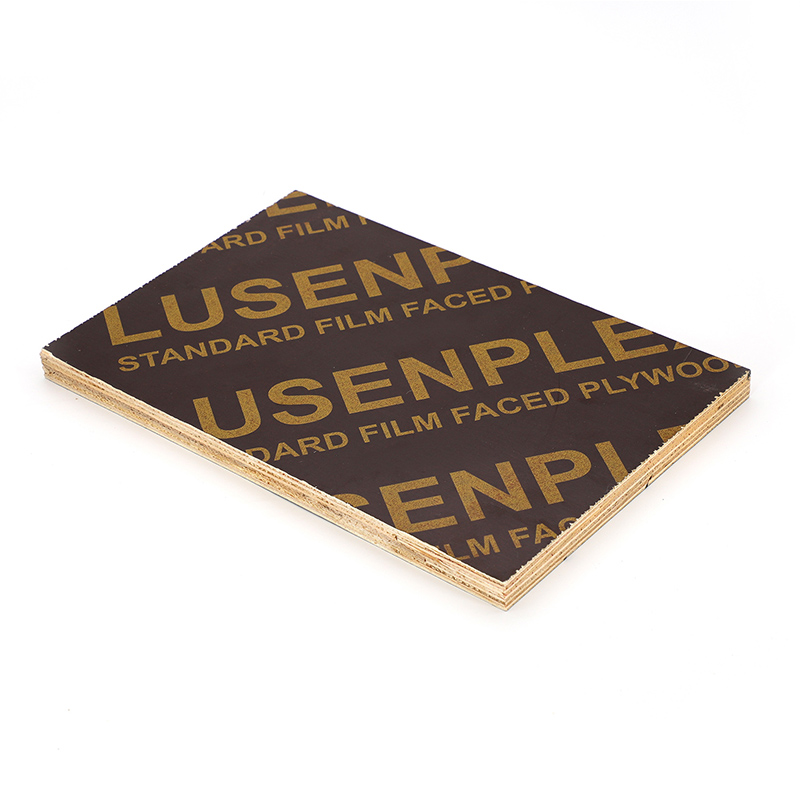

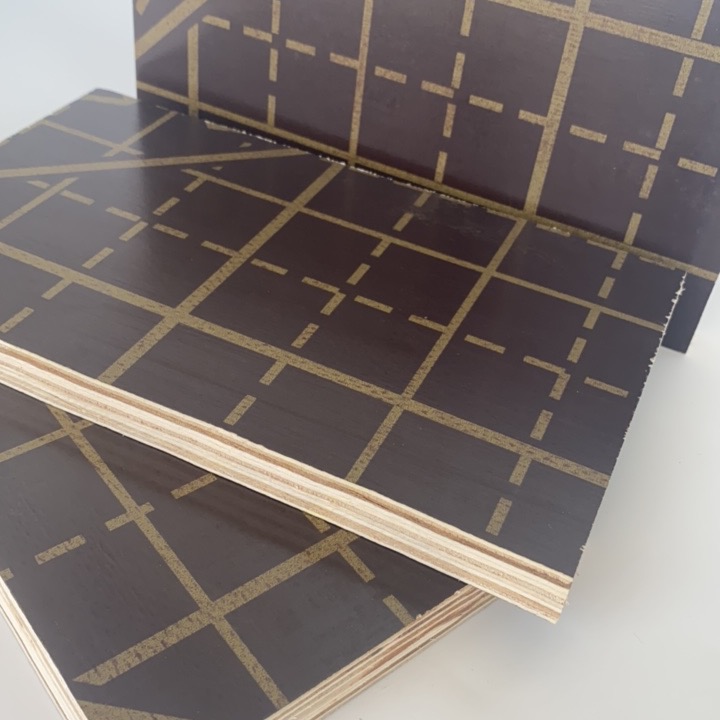

film faced plywood phenolic board

1) Easy to demould, release agent free, nonstick cement, concrete surface is very smooth.

Email Details

2) Light in weight, easy to use, can be cutted to any size.

3) More reuse times than normal film faced plywood.

4) Waterproof performance is perfect and wear resistant -

Film Faced Plywood China

1, Anti-smoke: It is made of PVC high-gloss film and easy to clean.

Email Details

2, wear resistance: special PET layer, sturdy and durable.

3, anti-humidity: surface film, reduce the direct contact between water and aluminum, and strong durability.

4, good touch: the surface has a film, the touch is smooth, changing the metal material cold and single feeling.

5, More colors: a variety of colors to choose from.

6, the price is moderate, cost-effective -

Hot

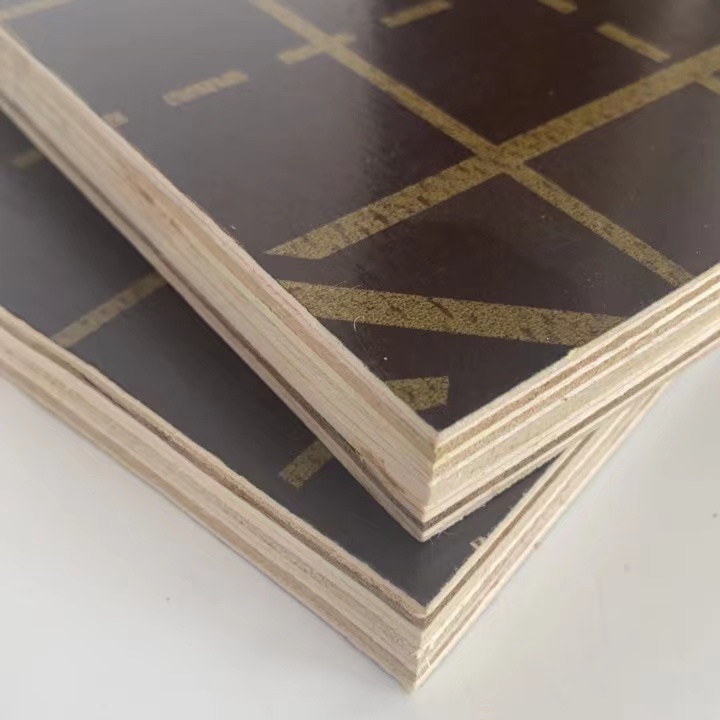

phenolic board

Features & Advantages :

Email Details

Film faced plywood is resistant to corrosion attack and water, easily combined with other materials and easy to clean and cut.Treating the film faced plywood's edges with waterproof paint makes it highly water-and wear-resistant. Due to its durability and easily handled surface, it can be used in open environment in construction and building. e.g. warehouses, railway wagons, floors and sidewalls of trucks etc. -

finger joint film faced plywood

1, Anti-smoke: It is made of PVC high-gloss film and easy to clean.

Email Details

2, wear resistance: special PET layer, sturdy and durable.

3, anti-humidity: surface film, reduce the direct contact between water and aluminum, and strong durability.

4, good touch: the surface has a film, the touch is smooth, changing the metal material cold and single feeling.

5, More colors: a variety of colors to choose from.

6, the price is moderate, cost-effective -

Hot

concrete formwork film faced plywood

Features & Advantages:

Email Details

Film faced plywood is resistant to corrosion attack and water, easily combined with other materials and easy to clean and cut.Treating the film faced plywood's edges with waterproof paint makes it highly water-and wear-resistant. Due to its durability and easily handled surface, it can be used in open environment in construction and building. e.g. warehouses, railway wagons, floors and sidewalls of trucks etc. -

construction grade film faced plywood

1) Easy to demould, release agent free, nonstick cement, concrete surface is very smooth.

Email Details

2) Light in weight, easy to use, can be cutted to any size.

3) More reuse times than normal film faced plywood.

4) Waterproof performance is perfect and wear resistant -

Hot

marine plywood

1. Transference to concrete is set up very easily, so good for construction work.

Email Details

2.Waterproof, Wear-resistant, anti-cracking. -

film faced shuttering plywood

1) Easy to demould, release agent free, nonstick cement, concrete surface is very smooth.

Email Details

2) Light in weight, easy to use, can be cutted to any size.

3) More reuse times than normal film faced plywood.

4) Waterproof performance is perfect and wear resistant