Film Faced Plywood China

1, Anti-smoke: It is made of PVC high-gloss film and easy to clean.

2, wear resistance: special PET layer, sturdy and durable.

3, anti-humidity: surface film, reduce the direct contact between water and aluminum, and strong durability.

4, good touch: the surface has a film, the touch is smooth, changing the metal material cold and single feeling.

5, More colors: a variety of colors to choose from.

6, the price is moderate, cost-effective

Film Faced Plywood China

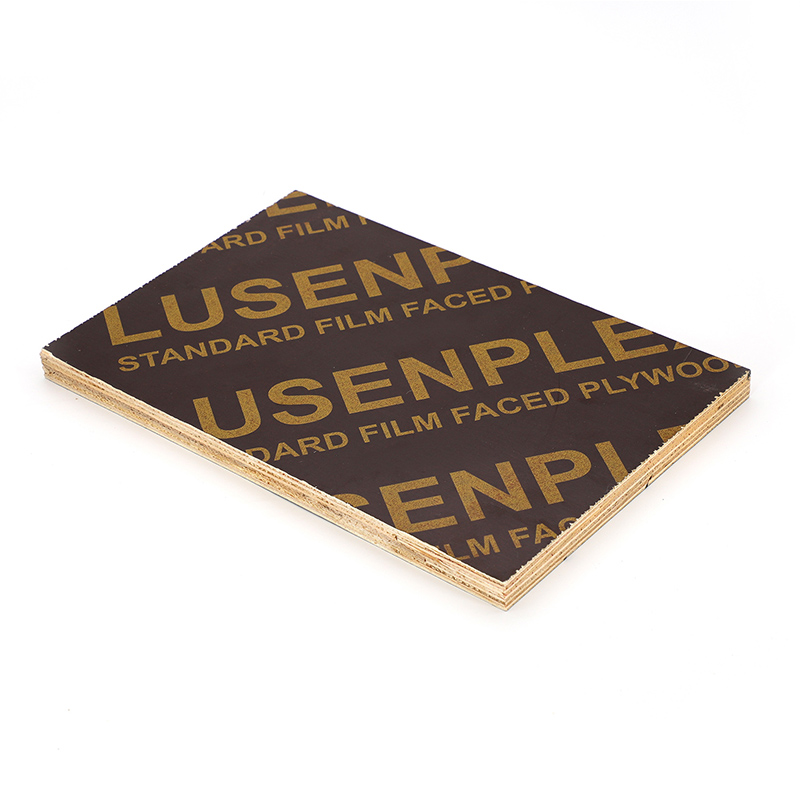

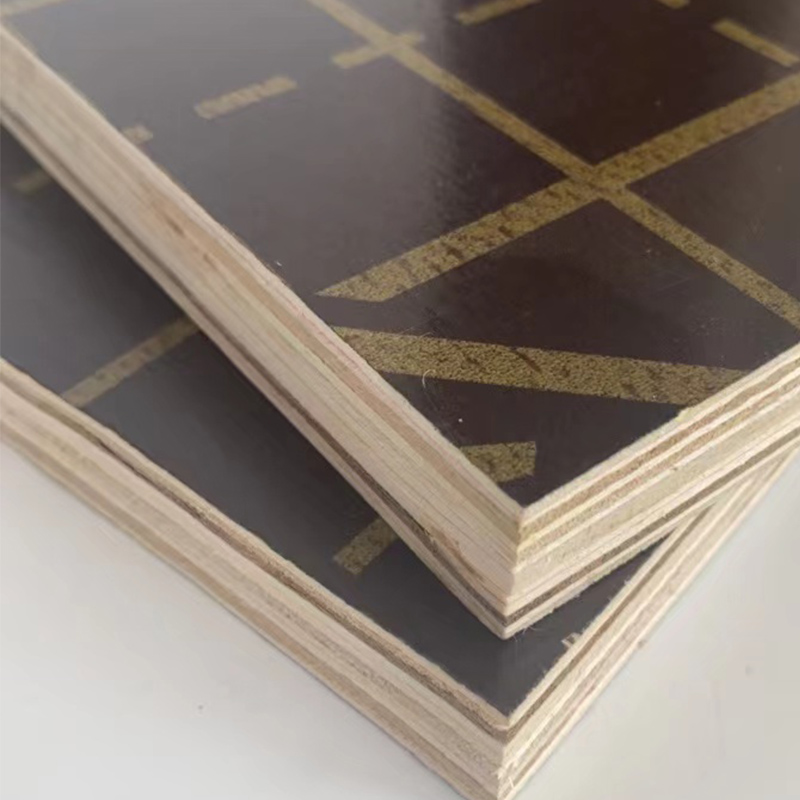

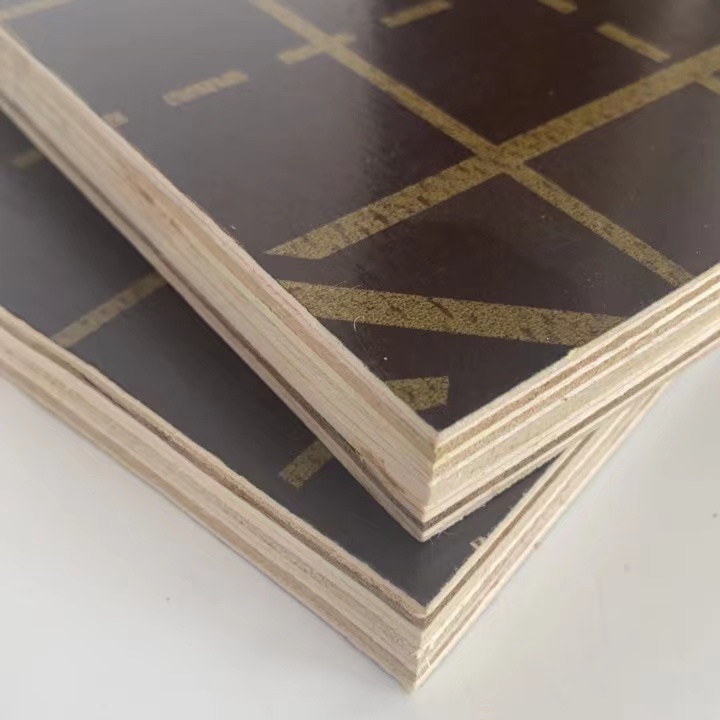

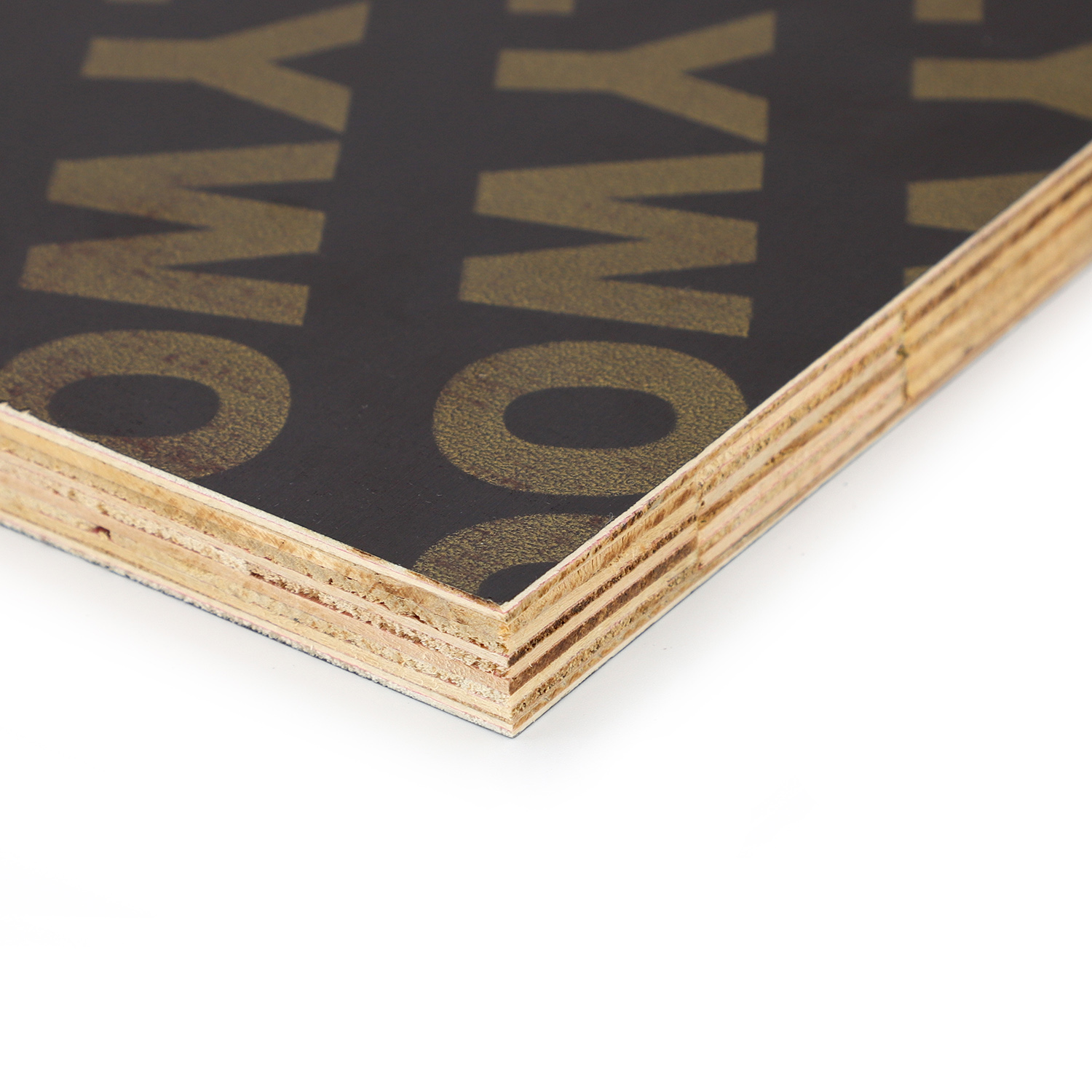

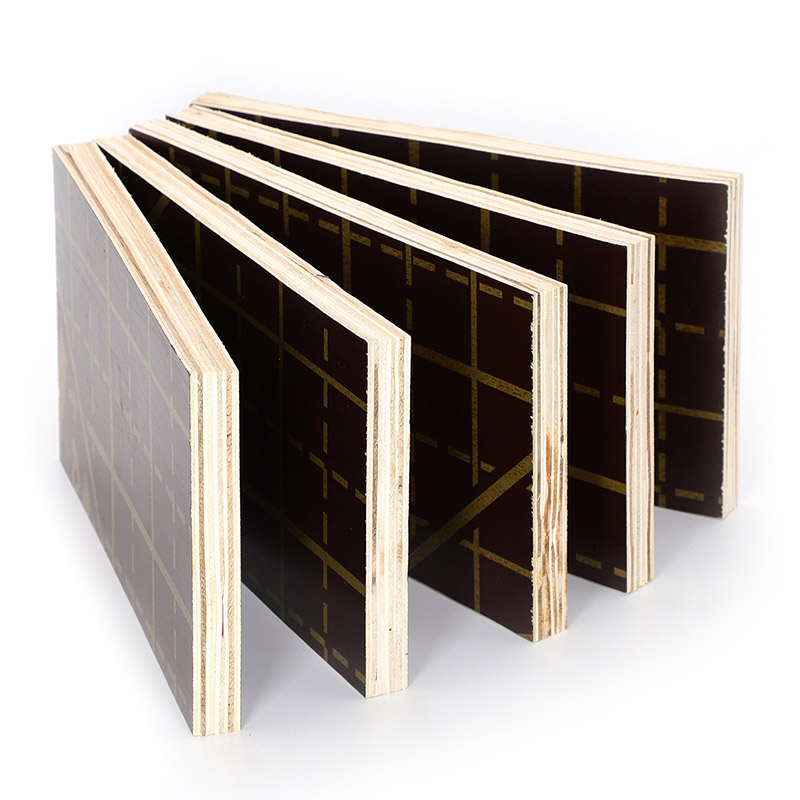

Film faced plywood is an exterior plywood used in building and construction projects. It has a special film coating on its surface made from phenol or melamine on either or both sides which gives the plywood a higher resistance to moisture, abrasion, chemical degradation and fungal attack compared to ordinary plywood.

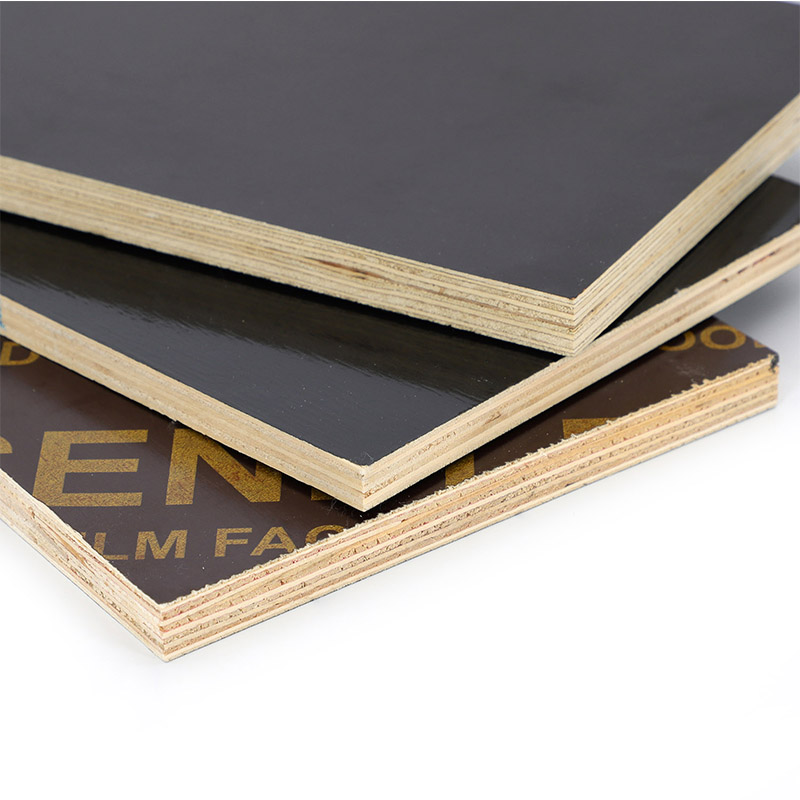

Because of its increased stability and resistance to moisture, ultraviolet radiation and corrosive chemicals, film-faced plywood is ideal for outdoor applications such as the external surfaces of new buildings. The extra film layer and acrylic varnished edges of this type of plywood make it more durable and less able to distort when used outdoors in harsh weather and adverse conditions. Buildings in direct sunlight are less prone to wear and tear if they are made from film-faced plywood, at least as part of the overall structure.

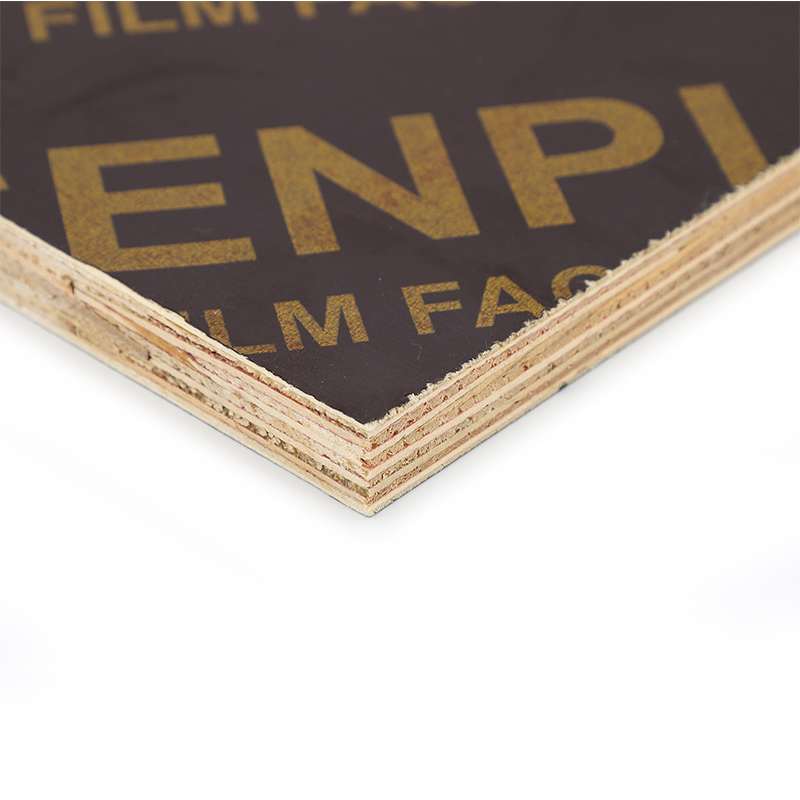

The plywood is useful for forming level molding boards and girder molding boards, which need to be resistant to strong forces, large amounts of fast-flowing water and yet still maintain their structural integrity and shape. There is a choice of thicknesses available, depending on requirements, from 12mm, 15mm and 18mm to 21mm, 24mm and 27mm. Some examples can reach 30mm.

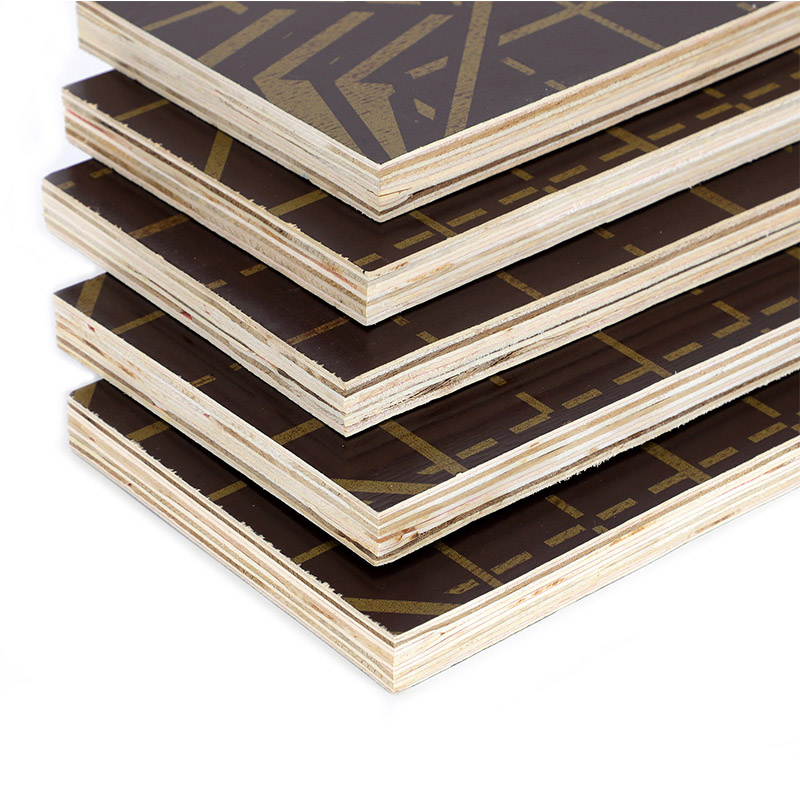

Main material | Eucalyptus, poplar, birch etc |

Glue | Melamine, WBP, Phenolic, E1, E2 etc. |

Size | 1220*2440mm or as requested |

| Thickness | 9mm,12mm,15mm,17mm,18mm,21mm etc. |

| Face/Back | Black, brown, green, and red. |

Moisture content | 8%~15% at shipment time |

| Packing | Standard export packing: pallet with plastic and metal strips. |

Tolerance | T: ±0.5mm; W: ±2mm; L: ±2mm |

| Application | construction, engineering |

MOQ | 20CBM or 1*20GP |

Features & Advantages

Film faced plywood is resistant to corrosion attack and water, easily combined with other materials and easy to clean and cut.

Treating the film faced plywood's edges with waterproof paint makes it highly water-and wear-resistant.

Due to its durability and easily handled surface, it can be used in open environment in construction and building.

e.g. warehouses, railway wagons, floors and sidewalls of trucks etc.

Our Service

1. With many years of experience in the professional technical team and after-sales team, we are always here to help you when there is anything wrong with product, and give back the solutions asap.

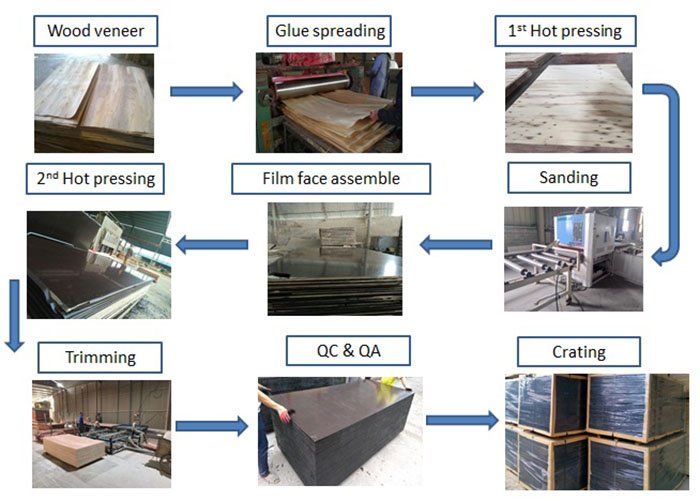

2. The Most advanced machinery and a strict quality control team.

3. Many production lines and experienced workers, so we have a stable supply and on-time delivery service.

4. Accept many standard production according to customers' requirement.

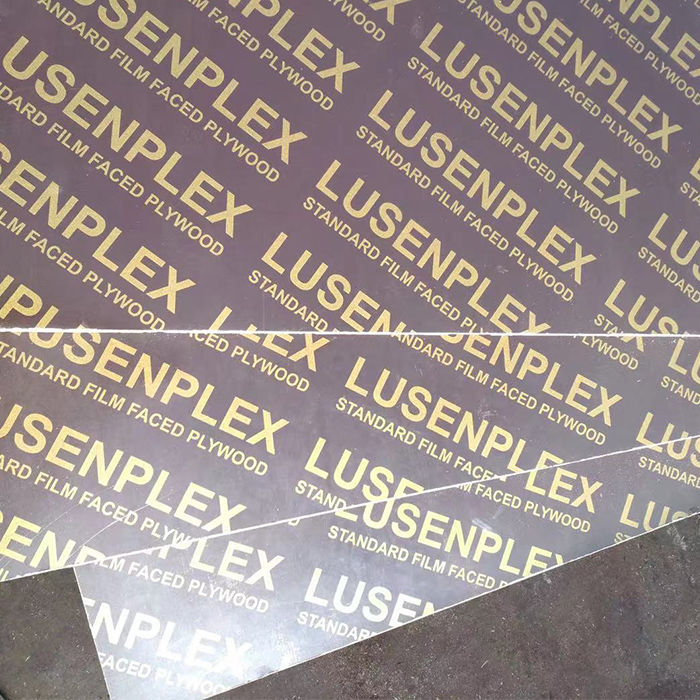

5. Provide OEM or ODM for our customers.

Q1. What are your main products?

A: The main business of Linyi Lusen is the producing and exporting of film faced plywood, commercial plywood,MDF,OSB,particle board ,veneer and some other wood products etc.

Q2. Are the samples available?

A: Yes, the sample is free and freight charge would be collected in your side.

Q3. What is your quality guarantee?

A: We have set up a product quality control team. We have a Product Testing People and an experienced QC team, every shipment will be strictly tested and inspected.

Q4: How long is your delivery time?

A: It is according to quantity, for less than 90cbm(2*40HQ) generally is 7-15 days after received the deposit, and it will be faster if the goods are in stock.

Q5: Could you accept OEM and customize?

A: Yes, we can customize plywood according to your sample or drawing.